Engineers at The University of Manchester have unlocked the secrets to designing a robot capable of jumping 120 metres – higher than any other jumping robot designed to date.

Using a combination of mathematics, computer simulations, and laboratory experiments, the researchers have discovered how to design a robot with the optimum size, shape and the arrangement of its parts, allowing it to jump high enough to clear obstacles many times its own size.

The current highest-jumping robot can reach up to 33 metres, which is equivalent to 110 times its own size. Now, researchers have found out how to design a robot that could jump over 120 metres in the air – that’s more than the height of Big Ben’s tower.

The advancement, published in the journal Mechanism and Machine Theory, will revolutionise applications ranging from planetary exploration to disaster rescue to surveillance of hazardous or inaccessible spaces.

Co-author Dr John Lo, Research Associate in Space Robotics at The University of Manchester, said: “Robots are traditionally designed to move by rolling on wheels or using legs to walk, but jumping provides an effective way of travelling around locations where the terrain is very uneven, or where there are a lot of obstacles, such as inside caves, through forests, over boulders, or even the surface of other planets in space.

“While jumping robots already exist, there are several big challenges in the design of these jumping machines, the main one being to jump high enough to overcome large and complicated obstacles. Our design would dramatically improve the energy efficiency and performance of spring-driven jumping robots.”

The researchers found that traditional jumping robots often take off before fully releasing their stored spring energy, resulting in inefficient jumps and limiting their maximum height. They also found that they wasted energy by moving side to side or rotating instead of moving straight up.

The new designs must focus on removing these undesirable movements while maintaining the necessary structural strength and stiffness.

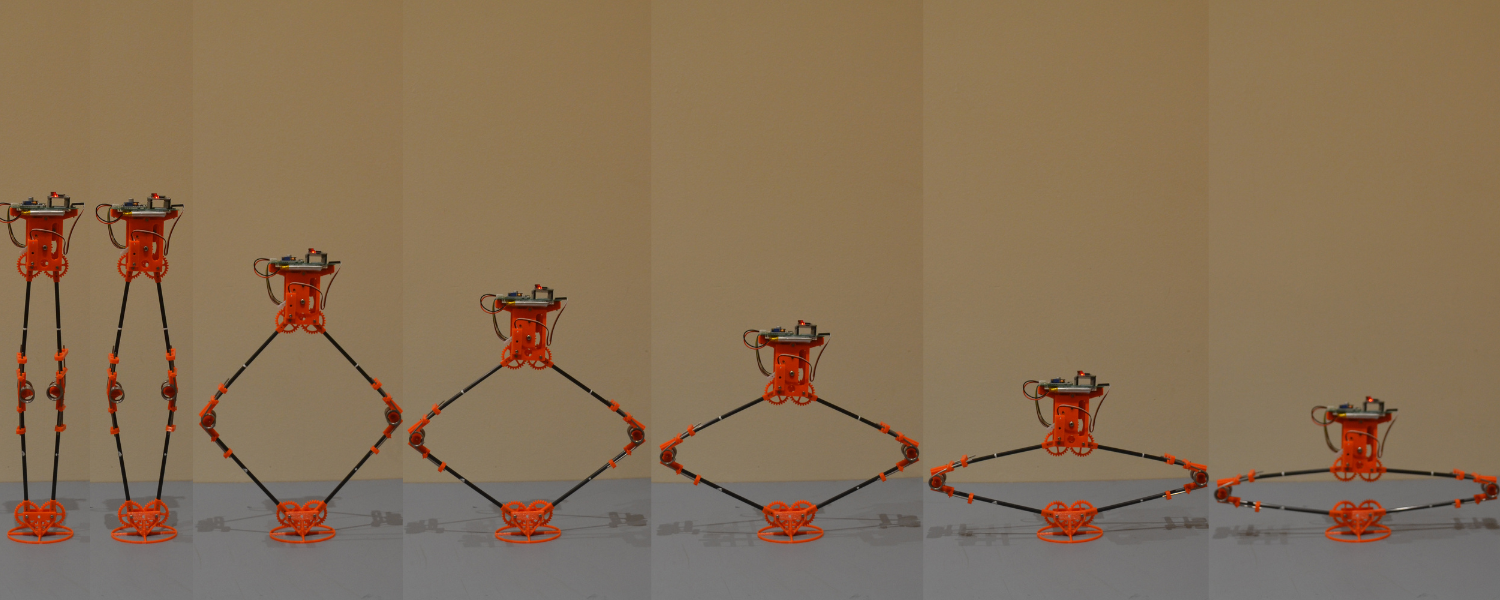

Co-author Dr Ben Parslew, Senior Lecturer in Aerospace Engineering, said: “There were so many questions to answer and decisions to make about the shape of the robot, such as should it have legs to push off the ground like a kangaroo, or should it be more like an engineered piston with a giant spring? Should it be a simple symmetrical shape like a diamond, or should it be something more curved and organic? Then, after deciding this we need to think about the size of the robot – small robots are light and agile, but then large robots can carry bigger motors for more powerful jumps, so is the best option somewhere in the middle?

“Our structural redesigns redistribute the robot’s component mass towards the top and taper the structure towards the bottom. Lighter legs, in the shape of a prism and using springs that only stretch are all properties that we have shown to improve the performance and most importantly, the energy efficiency of the jumping robot.”

Although the researchers have found a practicable design option to significantly improve performance, their next goal is to control the direction of the jumps and find out how to harness the kinetic energy from its landing to improve the number of jumps the robot can do in a single charge. They will also explore more compact designs for space missions, making the robot easier to transport and deploy on the moon.